Why CNC Machining?

Constantly, With Great Speed

To keep up with growing demands, we can use milling machines at their highest speeds. Additionally, these devices are able to operate constantly for the entire seven days of the week without getting weary, stopping, or compromising in any way.

These features make it one of the best ways to make production quick, efficient, and scalable without incurring any costs, while also ensuring that the machine keeps a high level of accuracy.

Speed Up The Whole Production Line

Moving the human resources down the assembly line can increase the efficiency of manufacturing units by decoupling the production capacity from the necessary staffing levels. In high-production environments and when assembling the product is so sophisticated that it necessitates specialized knowledge that machines cannot imitate, manual assembly lines are known to be more productive.

Accuracy, Consistency

Precision turning machines avoid the chance of human mistake entering into the manufacturing process and resulting in faults because they operate autonomously and without any operator interference. The machines can give more accuracy with no errors when codes and software programs guide the entire operation.

Additionally, unless changed purposefully, these inputs remain essentially unchanged throughout the whole production process, cycle after cycle, maintaining consistency in the end goods. Additionally, the machines can run nonstop for extended periods of time without sacrificing the quality of the work they generate.

Reduce Your Cost

Given the benefits listed above, it should be obvious that using CNC machines for precise component turning may significantly reduce manufacturing costs. The first benefit is that it boosts production and assembly productivity while reducing wasteful material usage.

Similar to that, it lowers energy use and cuts these ongoing operating expenses. Additionally, it discharges any financial responsibility brought on by mishaps and events. Overall, it is one of the most comprehensive strategies to reduce operating costs without sacrificing the operation’s process or quality.

Free Consultation and Instant Quote

Send us your CAD file or 2D draft, with product requirements to get an instant quote.

Quick Production

With our GBA approved manufacturers, you can receive parts in as less as 3 days in Eastern South region.

Service with No Worries

We will keep reporting to you the production and shipping status once we get started.

Materials for CNC Machining

We cover a wide range of major metals for 3D Printing, CNC machining, Casting and Sheet Metal Fabrication, with applications in multiple industries. This enanbles customers to achieve both one-off prototypes and end-use custom parts.

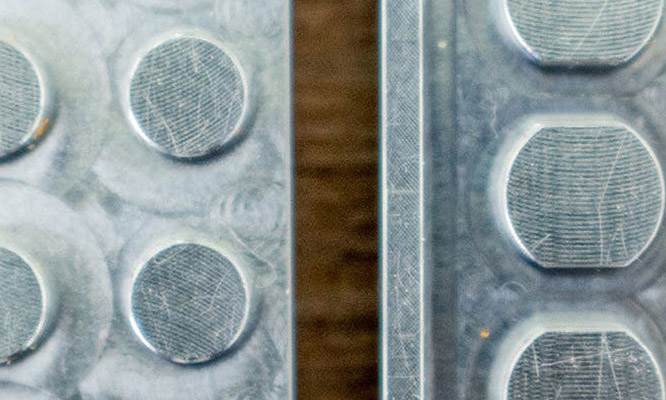

Aluminium

- Low weight

- Fast Building

- High strength and hardness

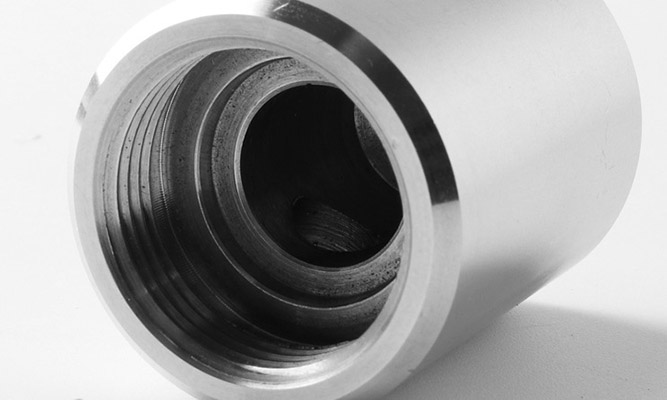

Stainless Steel

- Can apply to Food Processing

- Easilv machined into diverse shapes

- Excellent strength, corrosion resistant

Titanium Alloy

- Lightweight & BIo-compatible

- sports, Medical & Aerospace use

- Excellent resistance to cavitation

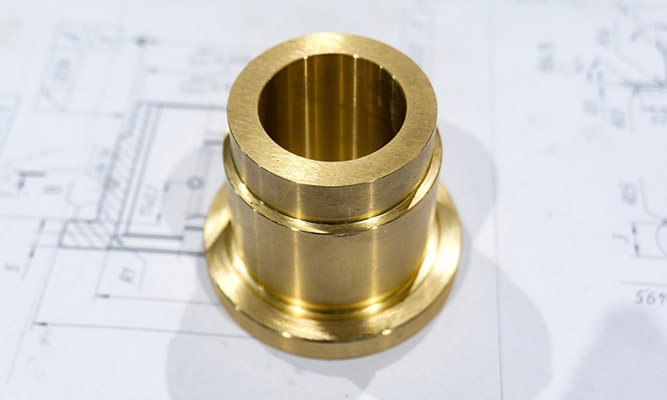

Copper Alloy

- Strong alloy with corrosion resistance

- Unlike iron, neither brass nor bronze rusts

- Jewelry size to large sculptures

Standard: Sand surfaces to remove build lines and bead blasted.

Anodized: Electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish

Heat Treated: Use of heating or chilling, normally to extreme temperatures, to achieve a desired result such as hardening or softening of a material

Polished: Sand surfaces to remove build lines and then apply polishing compound until desired surface finish is reached.

Metal Plated: Aluminum can be plated with a wide range of metals to increase its corrosion resistance, increase wear resistance, or improve overall aesthetics. Both electroplating and electroless plating are possible. Some common metals include tin, nickel, electroless nickel, gold, and silver.

Powder Coating: Powder coating is a robust option for coloring aluminum sheet metal parts while also adding a measure of corrosion resistance.

Additional post-processing: Includes CNC milling, lathing & EDM

Other Manufacturing Services

To know more, contact us for a free consultation and instant quote.